Reducing complexity.

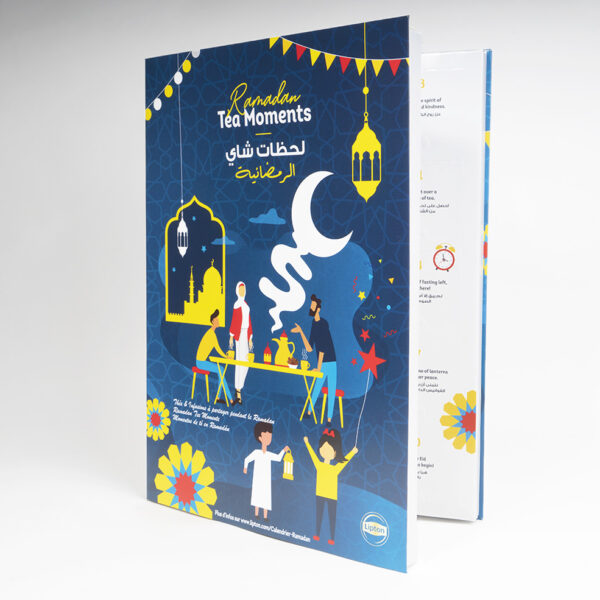

The Creative studio at Alexir were briefed by one of their customers to make palpable changes to an advent calendar format, from the profile design right through to the printing and packing.

The original design of the advent calendar had multiple challenges both in the pack format and in the packing.

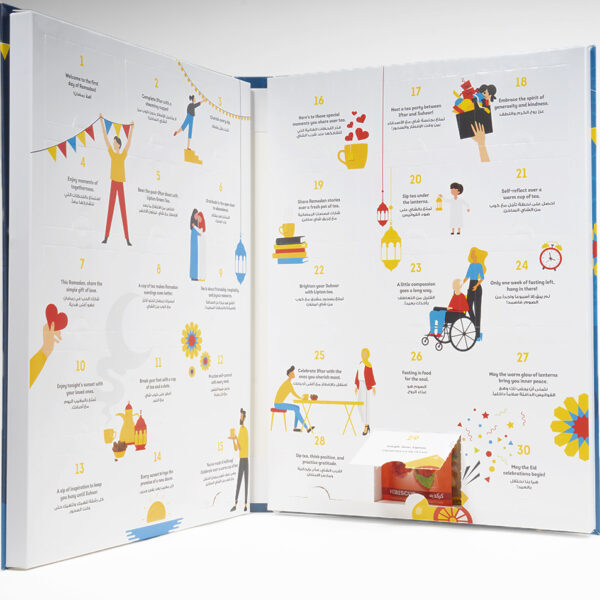

The fundamental issue with the pack format lay in its large footprint with a sizeable amount of folding box board being used, meaning it would not fit onto one printed sheet.

This sometimes can lead to inconsistency of print colour and graphic designers also struggle to maintain a ‘flow’ of creative artwork across three individual print items.

The constructional designers created a profile of the outer cover and two inner packs from one sheet of solid board. This reduced the footprint as the inner packs were no longer having to be stuck to the inside of the cover, making this part essentially ‘two layers’.

With the profile on the same print sheet, this avoided inconsistencies of print colour and gave the graphic designers one single canvas to work with.

Now that the outside cover had been simplified for the packing teams, it was key to find a solution to replace the 12 board components that made up the two trays. Our in-house procurement team explored various material options and the customer opted for a bespoke thermoformed pulp tray with 15 cavities each, sized for two tea bags to sit in securely.

3D printed trays were produced for fast approval and the tooling and manufacture of the trays were overseen by the project manager, in conjunction with the buying team. The packing teams now only had to pack the tea bags into the two pulp trays, insert these into the main body of the calendar and seal the packs with a tamper-evident sticker.

The simplicity of the erection and packing would dramatically increase the speed on the packing lines and would therefore decrease costs by at least 25%. Also, the design of the new final printed and packed advent calendar reduced board by 65%.

This complex packaging project is a perfect example of how our multiple services complement each other and enable the customer to benefit from an end-to-end solution, all within one partnership. The entire project was managed by one person, meaning the customer only had to deal with one contact all the way through the process. For a brand owner, dealing with numerous packaging substrates and suppliers can be very time-consuming and resource-heavy.

If you are looking for a multi-service solution, from our creative studio, to manufacturing and sourcing, through to co-packing, please contact us.