Two sites. One powerhouse.

From structural design and carton production to co-packing and fulfilment, our facilities are purpose-built to move fast, scale smart and deliver. While others rely on outsourcing, we’ve invested in the machinery, systems and people that make excellence possible in-house, so you’re never left waiting or wondering.

We manage the full packaging cycle:

- Creative and structural design

- Solid board carton manufacturing

- Material sourcing and sampling

- Co-packing for dry and ambient goods

- Fulfilment, boxing and shipping

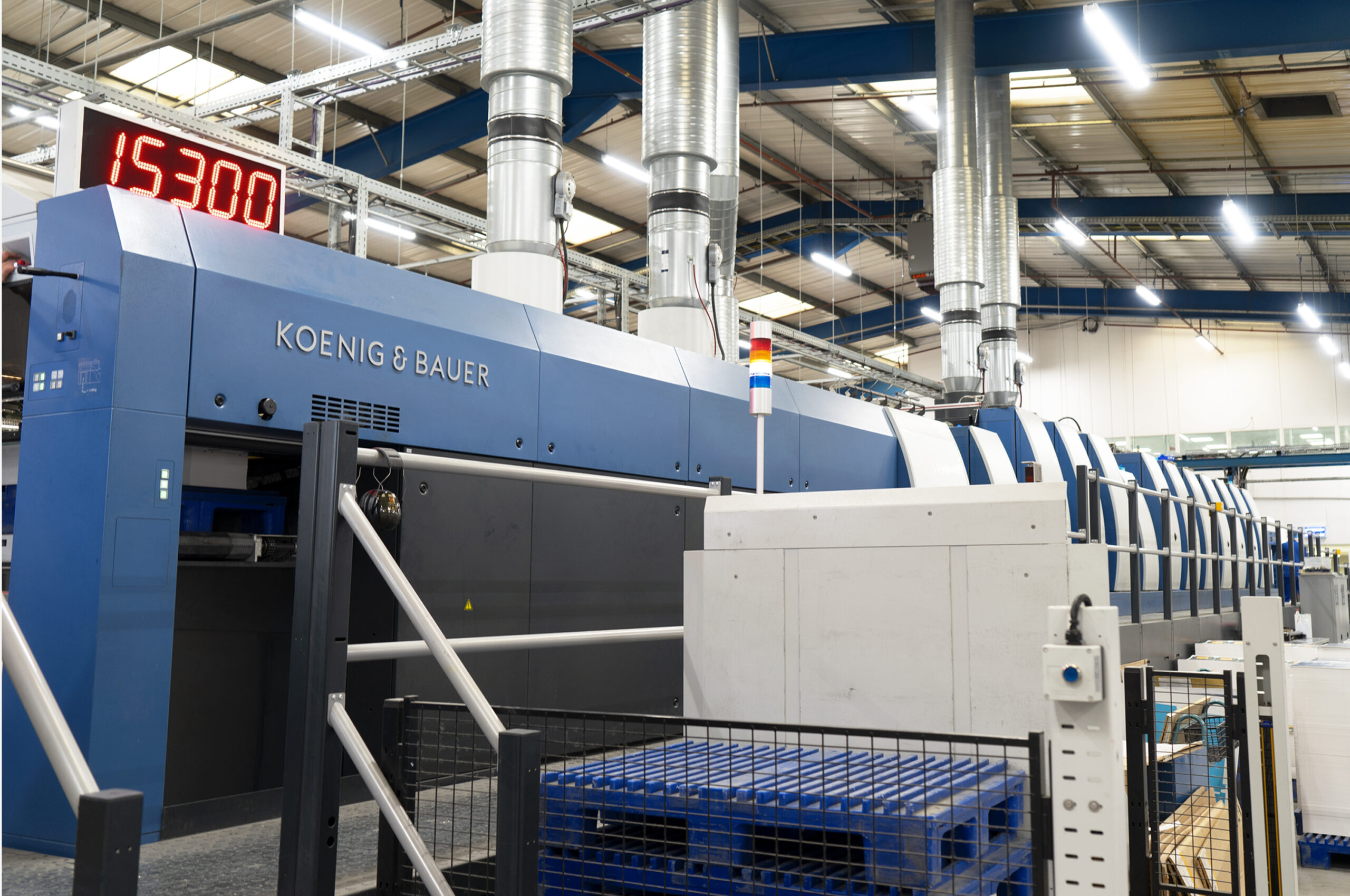

Engineered for the future

We don’t just keep up with industry standards; we invest to stay ahead. Our commitment to innovation means we’re constantly upgrading our technology and processes to deliver better quality, faster turnaround times, and smarter solutions.

Whether you’re launching a new product, scaling an existing one, or exploring something never done before, our sites are fully equipped to meet the challenge.

We continually reinvest in:

Automation and speed

for faster production and reduced waste

Data-driven quality control

ensuring product integrity every time.

Sustainability-focused upgrades

improving energy efficiency and reducing material waste.

Custom-built co-packing lines

tailored for dry food, supplements and premium gift sets.

Working like clockwork

We invest in our team as much as our equipment to ensure the highest standards are seen as the baseline. Our team are regularly trained and kept sharp to deal with the demands of fulfilment. Whether they’re an engineer, or a floor worker, our team are all respected as the people that keep the whole operation working like clockwork.

Capability and control

With Alexir, you get:

- Faster lead times

- Fewer suppliers

- No crossed wires

- Consistent quality

- Lower risk at every stage

- A proven, reliable supply chain partner

All underpinned by the tools, tech and team to make things happen, no excuses.

TESTIMONIALS